In the fast-paced world of manufacturing, plays a crucial role in ensuring the success of any metal fabrication project. At our US metal fabrication company, we understand the importance of creating prototypes to validate designs, identify potential issues, and streamline production. This essential step ensures high-quality results while saving time and resources in the long run.

Here are some of the top advantages of prototyping in the overall metal fabrication process.

Request a Quote for Our Prototyping Services

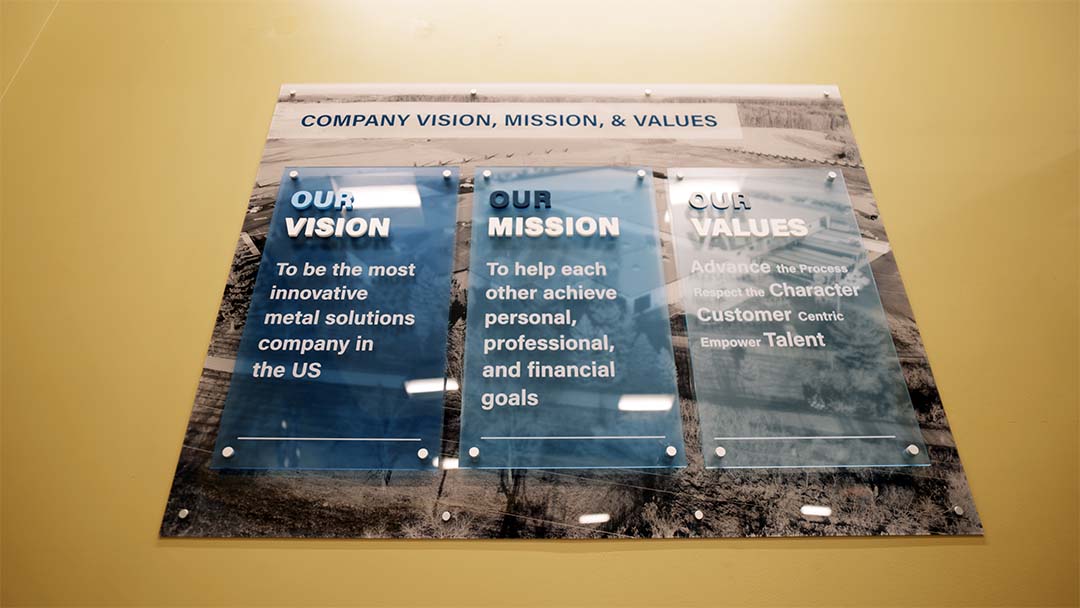

Ready to take the next step? DeWys Metal Solutions is proud to serve as your #1 choice in a US metal fabrication company. To take advantage of our prototyping services, please call (616) 677-5281. You may also fill out our online contact form and a member of our team would be more than happy to answer any questions you may have. You may also contact Wyze Designs, which is part of our family of brands at DeWys Metal Solutions.